Custom forging dies for your component

In the hot pressing plant we manufacture your product exactly to specification

You need an individual tool for the production of your forged product? This is no problem at the hot forging plant. Our experienced employees manufacture customized forging dies for your product. In this way, they forge your component exactly to your specifications - even with complex geometric shapes and special alloys. In this way, we offer you maximum flexibility and individual variety in the hot forging plant. So commission your forging job with us and trust 60 years of experience.

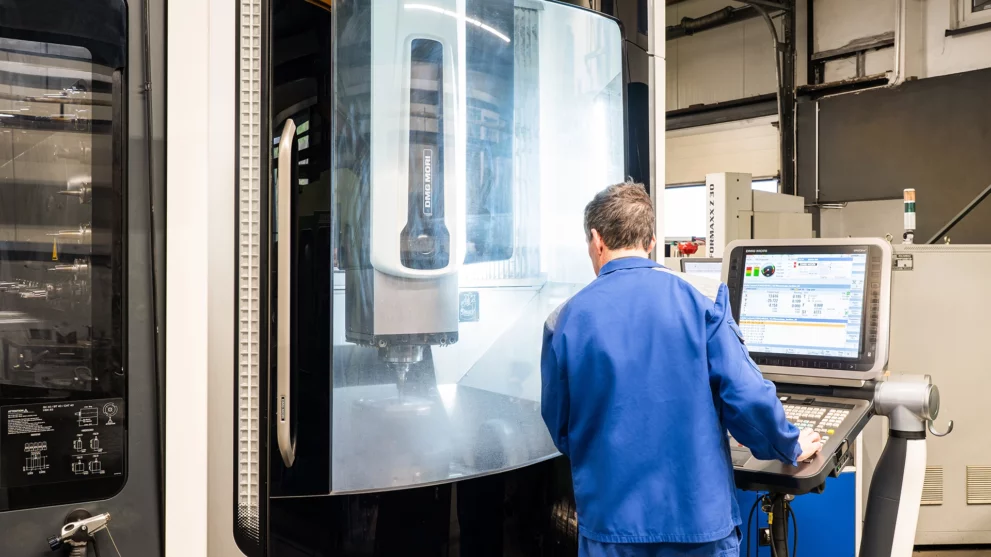

Particularly important in the production of forging dies is the use of high-quality turning and milling machines. These machine the material with the highest precision and care to bring it into the desired shape. Forging presses usually operate with forces of several hundred tons. This enables our employees to produce forging dies with precise and individual shapes.

The use of high-quality material is also essential for the manufacture of forging dies. These are special steels that have high resistance and hardness. This allows the hot press shop to produce forging dies and tools that maintain their quality even under high loads and temperatures.

Unbeatable advantages in the hot press plant

Suitable forging dies for your individual workpiece

The production of customized tools and forging dies in the hot press shop brings you many effective advantages. You receive exact components according to your specifications. Even complex profiles and special alloys are no problem for our employees. Whatever forged product you need, we will forge it exactly in the shape and with the material you desire.

- Customized solutions: Custom dies and molds can be designed and built specifically for your requirements to provide the perfect solution for any application.

- Increased efficiency: Custom dies and tools increase productivity by being designed and optimized specifically for the task you will later use them for.

- Cost savings: Custom dies and tooling help reduce your costs by increasing efficiency and reducing the number of tools needed.

- Higher quality: Customized dies and molds ensure higher quality of the parts produced, as they are precisely matched to the customer's requirements and tolerances.

- Flexibility: Customized dies and molds allow us to react quickly to changes in production or customer requirements.

- Uniqueness: Customized dies and tools allow you to create unique products that stand out from your competition. Our product portfolio already includes over 2500 different items.

You too can benefit from the unbeatable advantages of customized forging dies and set your forging product apart from the competition. Order your next forging at the hot pressing plant in the Eifel. Rely on 60 years of forging experience for your project. We are already looking forward to your order!