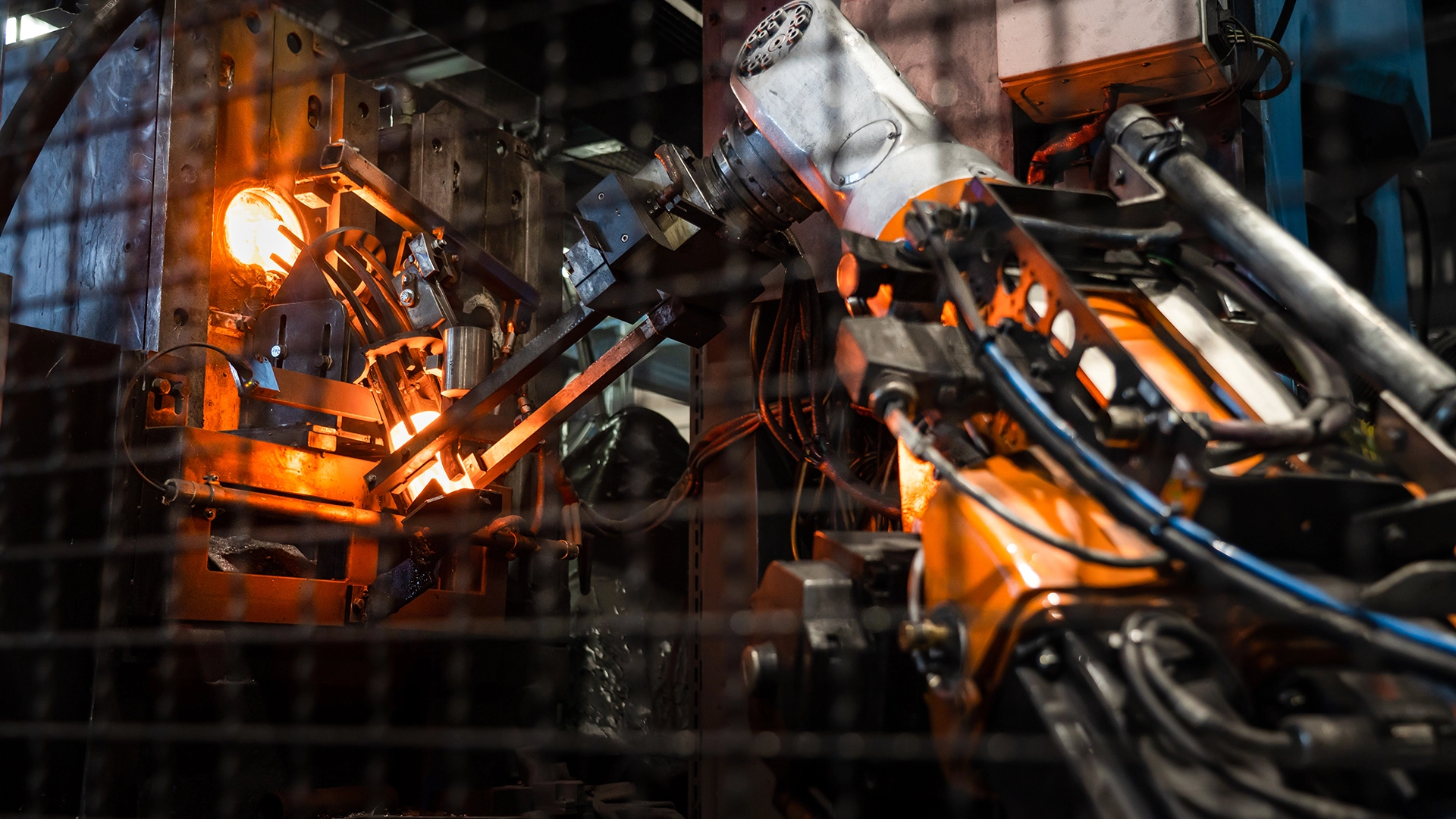

Forged parts for fittings

Individually manufactured in the hot pressing plant in the Eifel region of Germany

The Solid Forming is an efficient process for the production of fittings, as it generally produces little waste. It also requires less time and energy compared to other forming processes such as casting. The valves from the hot forging plant in the Eifel region of Germany are, thanks to our in-house, individual toolmaking very precise and durable. Rely on 60 years of forging experience and order your components from the Schachmann hot pressing plant.

Our products for your fittings

- Flanges

- Housing

- Cover

- SAE flanges

- Circular blanks

In hot forming, the workpiece to be machined is formed into the desired shape at temperatures of around 1000 °C and with a pressure of several hundred tons. At the hot forging plant in the Eifel region, we have our own in-house tool manufacturing facility. With these individual forging dies our employees can also produce complex forged parts for valves exactly to size.

Your component according to your specifications

Even with complex shapes and materials

One of the most important factors in the solid forming of valve components is the right choice of materials. These must have sufficient hot formability and meet the requirements of the subsequent area of application. For this reason, the hot stamping plant in Niederstadtfeld offers you a diverse selection of materials - from various steels to individual special alloys. In this way, we guarantee you maximum quality and flexibility.

The challenge in the manufacture of valves is the complicated geometry of the components. Fittings often have complex internal contours and undercuts that make uniform deformation an expert task. But thanks to 60 years of forging experience, the hot forging plant employees manufacture your valve components exactly to your specifications without any problems.

Trust this experience and have your forged products for fittings manufactured without compromise. Benefit from fast, individual and cost-efficient production of your components and commission your forging job at the hot pressing plant in Niederstadtfeld in the Vulkaneifel.