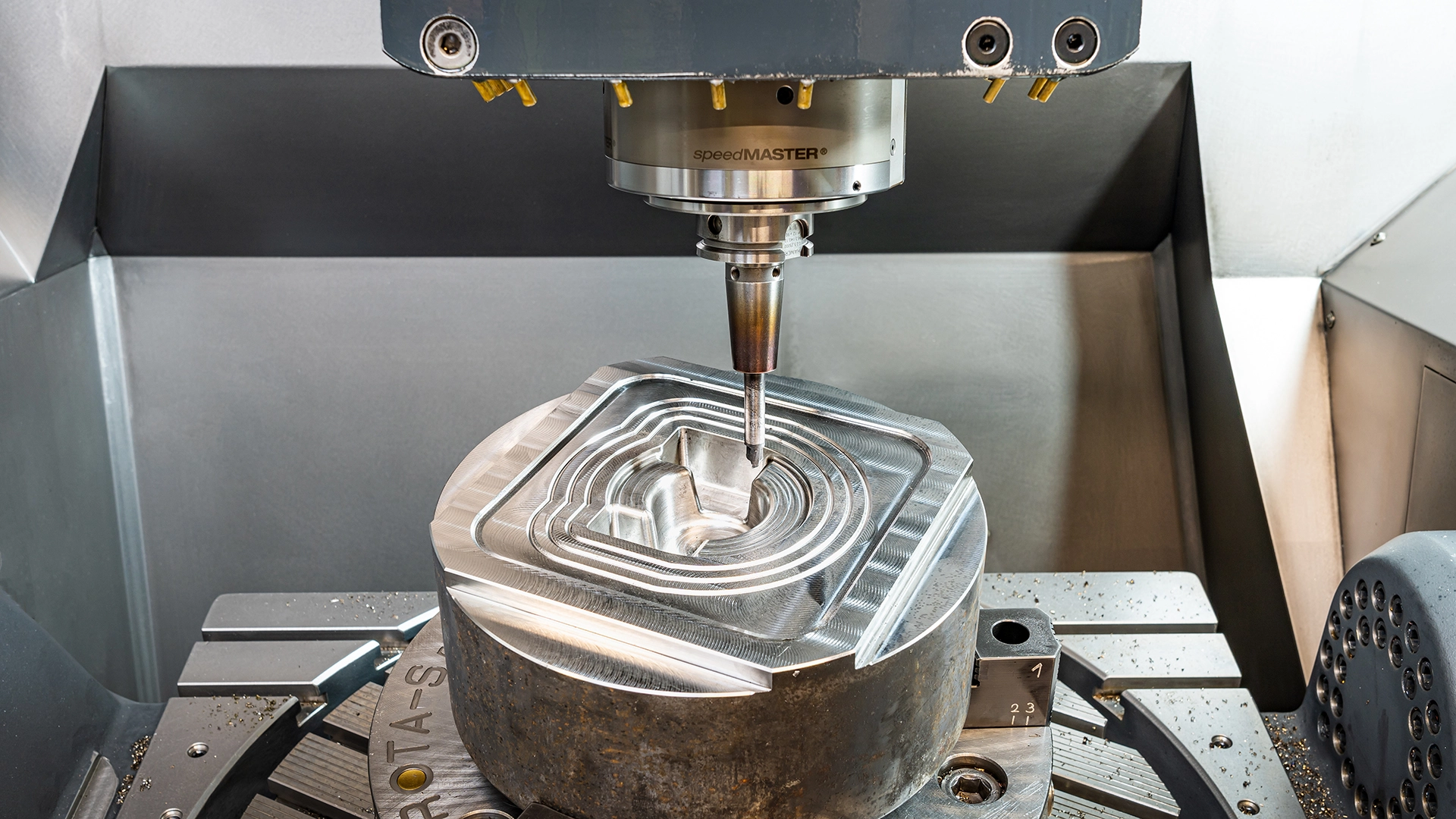

In-house toolmaking

High flexibility for your individual forged parts

The production of own forging dies and tools is a strength of the Schachmann hot forging plant. It enables us to forge individual components with complex shapes and profiles. Adjustments during production are also possible in this way. Thus, you enjoy an extraordinarily high degree of flexibility at the hot pressing plant, which facilitates the further realization of your project.

Our in-house tool shop offers you several advantages. Let us convince you and order your customized forged parts at the Schachmann hot pressing plant in the Eifel region. We are ready to support you with your project!

Our tools - your advantages

Flexibility in production

In-house construction of custom forging dies and matching tooling allows the Schachmann hot stamping plant to respond quickly to changes in product requirements. Our team can adapt the dies or design new dies to meet the requirements. This allows us to respond flexibly to your needs and, along the way, further increase our efficiency.

Cost optimization

The production of forging dies requires special knowledge and skills. In-house construction saves us the cost of purchasing dies externally. In addition, in-house manufacturing allows for better control over the manufacturing process, which enables a reduction in scrap and scrap costs.

Individuality of your products

In-house toolmaking enables the Schachmann hot stamping plant to design tools tailored to the requirements of each individual project. Every customer has specific needs - be it in terms of dimensions, shapes or special requirements for the material composition. With in-house tooling, these individual needs can be met, resulting in unique forgings.

Other tools from our production

In addition to forging dies, the employees at the Schachmann hot pressing plant also manufacture other tools that are used in the production of your forged parts:

Punching and trimming tools

Punching and deburring tools are used to punch precise holes in the forgings or to separate the excess burr from the forging. These tools are designed specifically for each project, which allows for customized production.

Shear blade

Shear blades are used to cut our bar material from 35 to 110 mm. Again, the in-house construction offers the possibility to adapt the shear blades to the individual requirements of each product and material.

Spare parts

In a production-intensive environment, the need for spare parts unavoidable. Building spare parts in-house allows the hot press shop to respond quickly to machine breakdowns, minimizing production delays and thus costs.